JMT JM-R Press Brake Series

You may not wish higher specification machine but of course this not mean you can not have accuracy and precision. We designed JM-R Series press brake for simple to use, performance and precision. Also for high quality bend accuracy and repeatability at least five-fold higher than conventional press brake.

JM-R Series press brake daylight, stroke & throat depth designs are specially for deep bends & long tools.

JMT JM-R SERIES PRESS BRAKE FEATURES

STANDARDS

– ST 44 Rigid Mono Block Steel Frame

– Synchronized Dual Cylinders

– Hoerbiger Hydraulic System

– Givi Misure Linear Measurement System

– Up and Down Moveable Control Unit Arm

– Delem DA 52 Control Unit

– X Axis Servo Motorized Back Gauge

– Manual Crowning

– JMT Top & Bottom Tool Clamping System

– Sliding & Height Adjustable Front Arms

OPTIONS

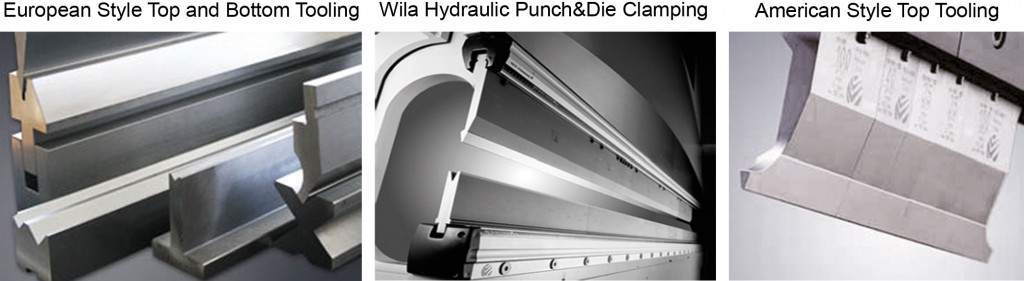

– Wila Hydraulic Clamping Systems

– European, American, Wila or Wilson Tools

– Laser Safety Device

– Special Throat Depths

– Tandem Preparation

– Oil Cooling & Heating Systems

– Delem DA 56 or Cybelec DNC 15

– CNC Motorized Crowning System

– X,R (with all control units) or

X,R,Z1-Z2 Axes Back Gauge (with Delem

DA 56 or Cybelec DNC 15)

– Special Finger Blocks

– Special Stroke & Open Heights

STANDARD JMT X AXES BACK GAUGE

Our standard JM-R series press brake is equipped with CNC controlled back gauge that automatically adjusts the X (depth) and R (manual) axes to ensure your material is always positioned accurately, resulting in higher quality finished parts. Axes movements are driven by Mitsubishi AC Servo Motors and Mitsubishi drives. Using the best components, such as HIWIN linear guides,ball screws,our back gauge movements are fast and precise,with X-axis speeds.

OPTIONAL X, R AXES BACK GAUGE SYSTEMS

2-axes CNC controlled back gauge that automatically adjusts the X (depth) and R (height) axes to ensure your material is always positioned accurately, resulting in

higher quality finished parts. Using the best components, such as HIWIN linear guides, ball screws, our back gauge movements are fast and precise.

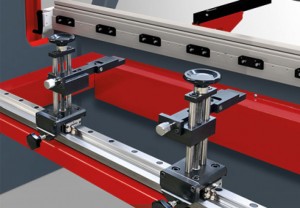

BACK GAUGE FINGER BLOCKS

Finger blocks are mounted on double a linear guide to be more rigid, which ensures accurate part positioning over a long period.

You can extend X Axes capacity with gaugeable 3rd position of finger blocks. Finger blocks are able to manually adjust positioning on the back gauge. Optionally you can add finger blocks to your back gauge system.

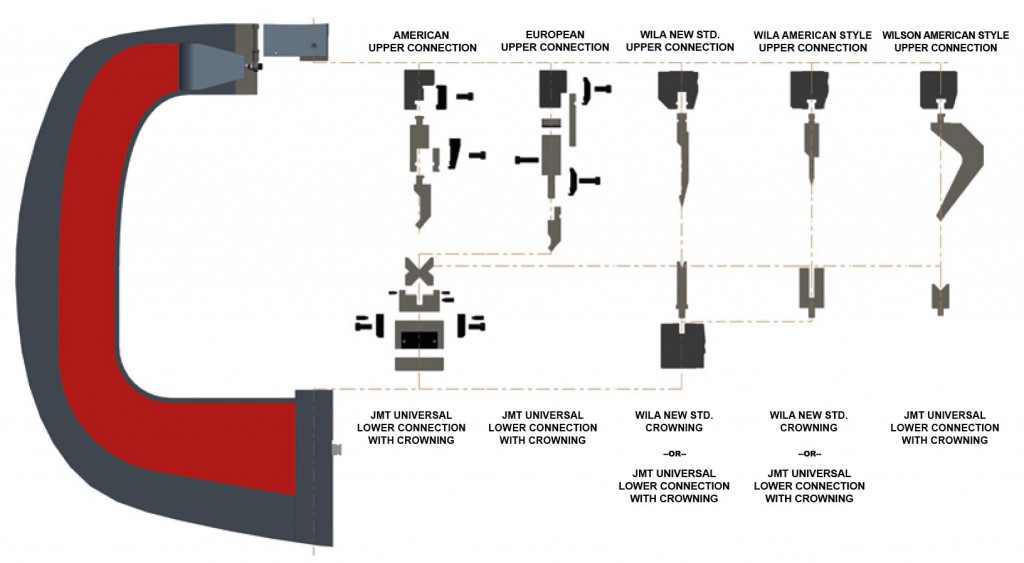

TOOLING (OPTIONAL)

JMT DIAGRAM CONNECTION TYPES (Tooling is Optional)

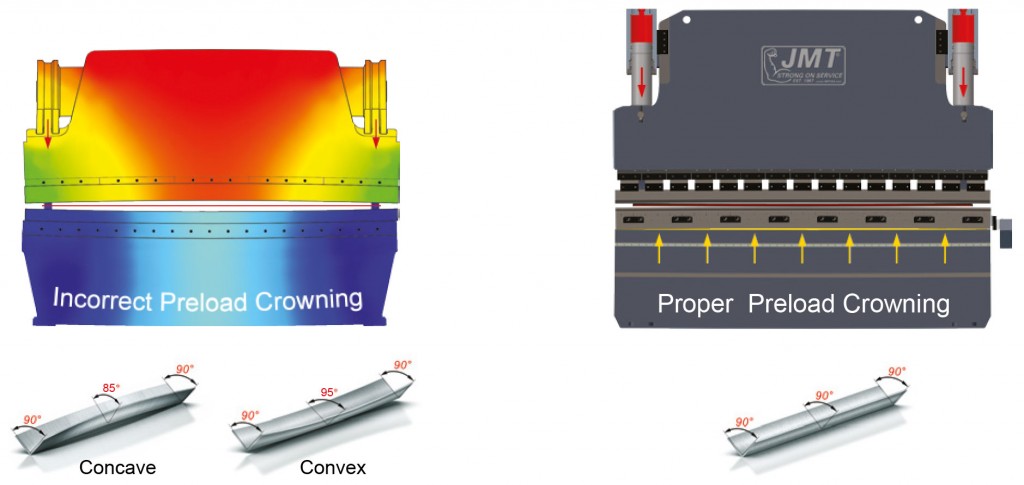

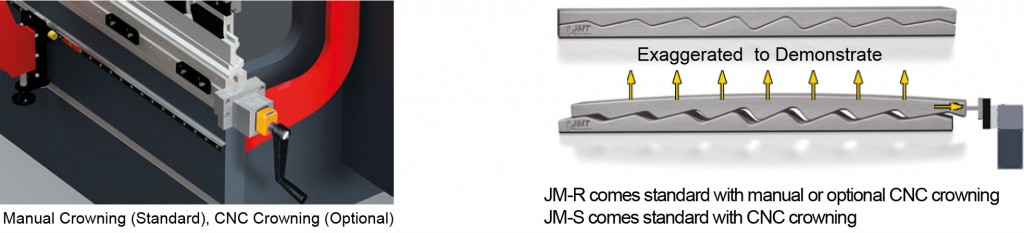

CROWNING SYSTEM

Manual crowning system is standard and cnc motorized crowning system is optional